IP20 Rated Factory Lighting

The IP (Ingress Protection) rating system is a global standard used to classify the degree of protection provided by an enclosure against the intrusion of solid particles and liquids. The IP20 rating specifically pertains to factory lighting and is an important indicator of its suitability for different industrial environments.

The first digit in the IP20 rating represents protection against solid objects. A rating of "2" means that the factory lighting fixture is protected against solid objects with a diameter greater than 12mm. In a factory setting, this provides a reasonable level of safeguard against larger debris that might be present. For example, it can prevent tools, small machinery parts, or chunks of raw materials from accidentally falling into the lighting fixture and causing damage to the internal components such as the light - emitting elements, electrical wiring, or the power supply.

The second digit, "0", indicates that the lighting fixture has no protection against liquids. This implies that IP20 - rated factory lights are not designed to withstand water ingress in any form, whether it's dripping, spraying, or immersion. Therefore, these lights should be installed in areas where there is no risk of water exposure, such as well - sheltered indoor factory spaces that are far from water - using processes or potential sources of leaks.

The housing of IP20 - rated factory lighting is typically made of durable materials such as metal (like aluminum or steel) or high - quality plastic. The design of the housing focuses on protecting the internal components from larger solid objects. It usually has openings or vents to allow for heat dissipation, as most factory lights generate heat during operation. However, these openings are designed in a way that they prevent the entry of objects larger than 12mm. For instance, the vents might be covered with a grille or a mesh with appropriately sized holes to maintain the required level of protection.

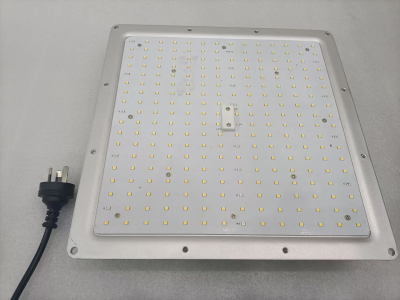

The light source in IP20 - rated factory lights can vary. It could be traditional lighting technologies like fluorescent lamps or high - intensity discharge (HID) lamps, but more commonly, it's light - emitting diodes (LEDs). LEDs are becoming increasingly popular due to their energy - efficiency and long lifespan. The light source is usually mounted on a printed circuit board (PCB) and surrounded by other components such as heat sinks (in the case of LEDs) to manage heat. The optical system, which includes lenses and reflectors, is designed to direct and distribute the light effectively. For example, in a manufacturing area, the optics might be configured to provide a uniform illumination pattern over a workbench or an assembly line.

The electrical components, such as ballasts (for fluorescent or HID lamps) or LED drivers (for LED lights), are housed within the enclosure. The wiring is carefully insulated and routed to prevent short - circuits and to protect against physical damage from the limited - sized solid objects that the housing is designed to keep out. However, due to the lack of liquid protection, the electrical system must be kept dry to ensure reliable operation.

IP20 - rated factory lighting is well - suited for general production areas where the environment is relatively dry and free from water - related activities. For example, in an automotive parts manufacturing factory, these lights can be used to illuminate the production lines where components are assembled, machined, or painted. The protection against larger solid objects ensures that the lights can withstand the normal wear and tear associated with a busy production floor.

In warehouses and storage facilities, IP20 - rated lights are useful for illuminating the aisles between storage racks and the storage areas themselves. Workers can easily locate products, operate forklifts, and perform inventory management tasks under the illumination provided by these lights. The fixtures can also withstand the occasional bump or impact from moving goods and equipment.

The most significant limitation of IP20 - rated factory lighting is its lack of protection against liquids. This means it's not suitable for areas where there is a high probability of water contact. For example, in a food processing factory where equipment is frequently washed down with water, or in a chemical plant with areas prone to leaks or spills, IP20 - rated lights would not be a good choice as water ingress could lead to short - circuits, damage to the electrical components, and ultimately, lighting failure.

While the rating provides some protection against larger solid objects, it offers limited defense against fine dust. In industrial environments where there is a significant amount of fine particulate matter, such as in textile mills or wood - working factories, the dust can gradually accumulate inside the lighting fixture. Over time, this can affect the heat dissipation of the light source, reduce the light output, and potentially lead to overheating and premature failure of the lighting system.

IP20 - rated factory lighting is generally more cost - effective compared to lighting fixtures with higher IP ratings. The manufacturing process for these lights doesn't require the complex and expensive seals and gaskets needed for higher levels of protection against liquids and fine dust. This cost - savings can be beneficial for factory owners, especially when lighting a large industrial space with a relatively clean and dry environment.

The design of IP20 - rated lights allows for efficient heat dissipation. The vents and openings in the housing, which are designed to keep out larger solid objects, also facilitate the flow of air around the internal components. This helps in cooling the light source and other electrical parts, which in turn can contribute to a longer lifespan and better performance of the lighting system.