Explosion-Proof LED Radar Sensor Lights: Revolutionizing Safety and Efficiency in Underground Mining

Introduction

Underground mining operations demand lighting systems that prioritize safety, energy efficiency, and adaptability to harsh environments. Traditional incandescent or fluorescent fixtures often fall short in these areas, posing risks of ignition in methane-rich atmospheres and requiring frequent maintenance. Enter explosion-proof LED radar sensor lights – a cutting-edge solution combining intrinsically safe design, motion-sensing intelligence, and rugged durability.

1. Technology Overview

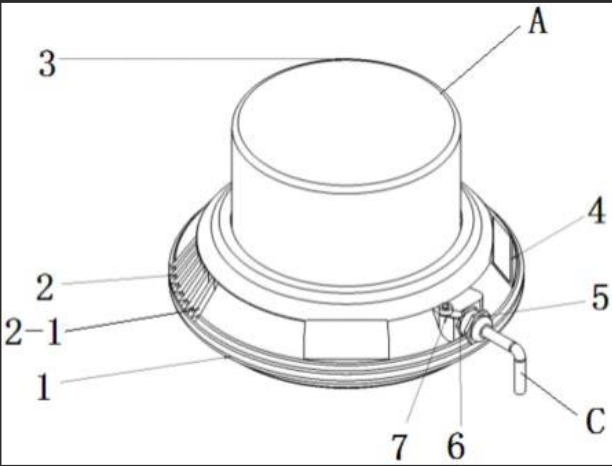

Core Components:

- Explosion-Proof Housing: Cast aluminum or stainless steel enclosures rated IP66/IP68, designed to contain internal sparks and withstand pressures up to 1.5MPa (per ATEX/IECEx standards).

- LED Modules: High-efficiency COB (Chip-on-Board) LEDs with ≤70°C surface temperature, eliminating ignition risks.

- Radar Sensors: 5.8GHz microwave motion detectors with adjustable detection ranges (3-15 meters) and 120° coverage angles.

How It Works:

The radar sensor emits high-frequency microwaves that detect subtle movements (even through dust or smoke). Upon sensing activity, the light brightens to 100% (e.g., 150 lux). After a preset delay (30s-30min), it dims to 20-30% standby brightness, reducing energy waste in unoccupied areas.

2. Key Advantages for Mining Applications

2.1 Enhanced Safety

- Hazard Mitigation: Certified for Zone 1/21 (explosive gas/dust atmospheres), preventing methane or coal dust ignition.

- Fail-Safe Design: Dual protection – thermal fuses cut power if temperatures exceed 85°C, while surge protectors guard against voltage spikes.

2.2 Energy Savings

- Adaptive Lighting: Radar-triggered dimming reduces energy use by 60-80% compared to always-on lights.

- Efficiency: 120-150 lm/W output vs. 15 lm/W for incandescent bulbs. Example: Replacing 10×100W incandescent lights with 30W LEDs saves ~2,500 kWh/month.

2.3 Maintenance Reduction

- 50,000-Hour Lifespan: Operates 5-7 years in 24/7 environments, minimizing tunnel access for replacements.

- Vibration Resistance: No filament or glass components – withstands shock from drilling/blasting activities.

3. Critical Applications in Mines

3.1 Haulage Drifts

Radar-activated full brightness ensures visibility for loaders/trucks approaching blind corners, dimming automatically post-transit to conserve energy.

3.2 Ventilation Shafts

Low standby brightness (20%) maintains minimal illumination, flaring up only during maintenance crew access.

3.3 Coal Face Zones

Dust-tight sensors reliably detect miner movements even in high particulate environments, ensuring safe illumination during excavation.

3.4 Emergency Escape Routes

Integrated battery backups (90-min runtime) activate during power outages, with motion sensing to guide evacuations.

4. Case Study: Copper Mine in Chile

Challenge: A subterranean copper mine faced frequent bulb failures (humidity/vibrations) and 35% energy waste from 24/7 lighting in low-traffic zones.

Solution: Installed 120× explosion-proof LED radar lights (100W equivalent, 30W actual) in haulage tunnels and rest areas.

Results (12 Months):

- Energy Savings: 68% reduction in lighting electricity costs ($18,500/year saved).

- Safety: Zero lighting-related ignition incidents despite methane concentrations up to 1.2%.

- Maintenance: Lamp replacements dropped from 15/month to 2/year.

5. Standards and Certifications

Global compliance ensures reliability:

- Explosion Proof: ATEX Directive 2014/34/EU (EU), IECEx (International), MSHA (US)

- Environmental: IK10 impact resistance, -40°C to +55°C operational range

- EMC: EN 55015, unaffected by nearby RF equipment

6. Future Trends

- AI Integration: Predictive analytics to track traffic patterns and optimize dimming schedules.

- Mesh Networking: Lights with Zigbee/LoRa communication for centralized monitoring via IoT platforms.