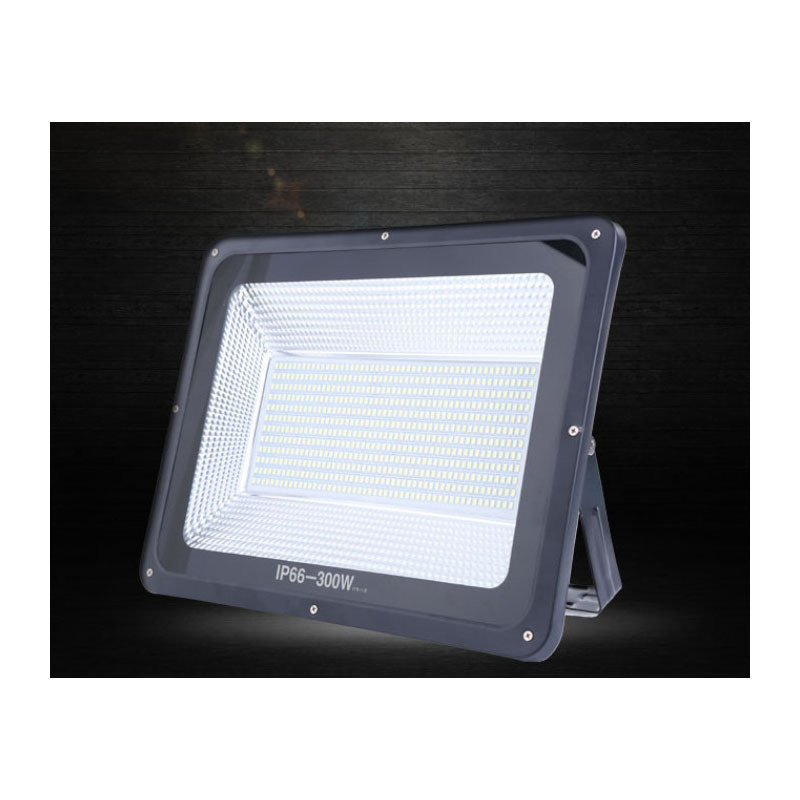

IP65 And Below Floodlights

The IP (Ingress Protection) rating is an international standard that indicates the level of protection a device, such as a floodlight, provides against the ingress of solid particles and liquids. The IP code consists of two digits. The first digit represents the protection against solid objects (ranging from 0 - 6), and the second digit represents the protection against liquids (ranging from 0 - 9).

Solid Particle Protection: The first digit '6' in IP65 means that the floodlight is completely protected against dust ingress. It can prevent even the tiniest dust particles from entering the enclosure of the floodlight. This is crucial for floodlights used in dusty environments such as construction sites, industrial workshops, or outdoor areas near unpaved roads. The sealed design helps to keep the internal components clean and free from the potential damage caused by dust accumulation, which could affect the performance of the light - emitting elements and other electrical components.

Liquid Protection: The second digit '5' indicates protection against water jets. A floodlight with an IP65 rating can withstand water projected by a nozzle from any direction. The typical test for this involves spraying water at a pressure of about 30 kPa (kilopascals) from a distance of around 3 meters for at least 3 minutes. This makes IP65 floodlights suitable for outdoor use in most weather conditions, including rain and light splashes from water sources. However, they are not designed to be submerged in water.

IPX3 and IPX4: These are common lower - level water - protection ratings. An IPX3 - rated floodlight is protected against spraying water at an angle up to 60 degrees from the vertical. It can handle light rain or water spray from a particular direction. IPX4 - rated floodlights are more resistant and can withstand water splashes from all directions. They are often used in areas where there is a possibility of occasional water exposure, such as in bathrooms (if used for decorative lighting) or in outdoor settings with limited water contact.

IP54: In the case of IP54, the first digit '5' means the floodlight is protected against dust ingress to a certain extent. It can prevent the harmful ingress of a limited amount of dust, which might not be as comprehensive as the protection offered by IP6 - rated floodlights. The second digit '4' provides protection against splashing water from all directions. This rating is suitable for environments that have a combination of some dust and water exposure, like in outdoor cafes or under covered walkways.

IP44: Here, the '4' for solid particle protection means that the floodlight can protect against objects larger than 1mm, such as wires or small tools. The second '4' for liquid protection is the same as in IP54, offering protection against splashing water from all directions. These floodlights can be used in areas where there is a lower risk of fine - dust ingress and where water splashes are a more significant concern.

Outdoor Building Illumination: IP65 floodlights are widely used to light up the exteriors of buildings, such as office buildings, hotels, and residential complexes. They can provide a bright and consistent light output even during rain or windy conditions, highlighting the architectural features and enhancing the security of the building.

Industrial Outdoor Lighting: In industrial settings like factories and warehouses, IP65 floodlights are used to illuminate outdoor work areas, storage yards, and loading docks. They can withstand the dust generated by industrial activities and the water from rain or industrial cleaning processes.

Sports Facilities: For outdoor sports fields and stadiums, IP65 floodlights are a popular choice. They can provide excellent illumination during games and training sessions, regardless of the weather, ensuring good visibility for athletes and spectators.

Indoor - Outdoor Transitional Areas: Floodlights with ratings like IPX3 - IPX4 are often used in covered patios, balconies, or entryways where they might be exposed to some water splashes from rain or from cleaning activities, but not to heavy water jets.

Residential Gardens: IP54 floodlights can be used in home gardens where there is a combination of some dust (from soil) and water exposure (from watering or rain). They can illuminate flower beds, pathways, or small garden structures.

Retail Storefronts: In areas where the floodlights are under awnings or overhangs and are not directly exposed to heavy rain or dust, lower - rated floodlights can be used to highlight store displays and signage.

Sealing and Gaskets: For IP65 floodlights, high - quality rubber or silicone gaskets are used to seal the enclosure tightly. The seams and joints of the housing are carefully designed to prevent any gaps through which dust or water could enter. In contrast, floodlights with lower IP ratings might have less - elaborate sealing mechanisms, depending on the level of protection required. For example, IPX3 - rated floodlights may have basic seals around the edges to prevent water from entering at a certain angle.

Drainage and Ventilation: Some floodlights with lower IP ratings, such as IP44, may have small drainage holes to allow any accumulated water to escape. However, for IP65 floodlights, the design is more focused on complete protection against water ingress without the need for drainage holes (as they are not designed to let water in). Ventilation is also a consideration. While IP65 floodlights need to balance protection against dust and water with the need to dissipate heat generated by the light source, floodlights with lower IP ratings may have more straightforward ventilation designs.

IP65 Floodlights: These generally require less maintenance due to their high - level protection. However, periodic inspection of the seals and gaskets is still necessary to ensure they remain intact and effective. If the seals are damaged, the floodlight's protection level could be compromised, leading to potential damage from dust or water. The internal components of IP65 floodlights are likely to have a longer lifespan as they are better protected from environmental factors.

Lower - Rated Floodlights: Floodlights with lower IP ratings may need more frequent maintenance. For example, those used in areas with more water exposure (like IPX4 - rated floodlights in a damp environment) may require checking for water damage or corrosion. The dust - protection capabilities of lower - rated floodlights mean that over time, they may accumulate more dust internally, which could affect the performance of the light source and other components. Therefore, regular cleaning and inspection are essential to maintain their performance and extend their lifespan.