Fixed Explosion Proof Light

A fixed explosion - proof light is a lighting fixture designed to be permanently installed in areas where there is a high risk of explosion due to the presence of flammable gases, vapors, or combustible dust. These lights play a crucial role in providing illumination while ensuring safety in hazardous industrial environments such as oil refineries, chemical plants, mines, and grain storage facilities.

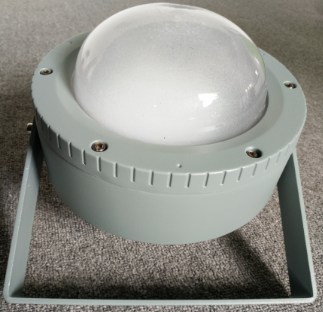

The housing of a fixed explosion - proof light is typically constructed from robust and durable materials. Cast aluminum is a popular choice as it offers excellent strength and is relatively lightweight. Stainless steel is also used, especially in corrosive environments, due to its high resistance to rust and chemical attack.

The housing is designed to be explosion - proof. It has a solid, sealed structure with thick walls to contain any potential internal explosion. The joints and seams are carefully sealed with high - quality gaskets, usually made of materials like silicone or neoprene. These gaskets can withstand high temperatures and pressures, ensuring that no hot gases or flames escape from the housing to ignite the surrounding explosive atmosphere.

The lens of the fixed explosion - proof light is an essential component for light transmission. It is often made of toughened glass or a high - grade, impact - resistant plastic. The lens provides a clear medium for the light to pass through, allowing for efficient illumination.

It is designed to have good optical properties to maximize the light output and to provide a uniform distribution of light. The lens also needs to be strong enough to withstand external impacts, such as from falling objects or accidental collisions. Some lenses may have a coating to enhance light diffusion, reducing glare and providing more comfortable illumination. In some cases, the lens may also be designed to protect against ultraviolet (UV) radiation.

A fixed explosion - proof light has a specific mounting mechanism that allows it to be securely attached to a wall, ceiling, pole, or other fixed structures. The mounting brackets or fixtures are usually made of the same durable materials as the housing and are designed to withstand the weight of the light and any external forces such as vibrations or wind loads.

The installation process is carefully designed to ensure that the light is properly grounded to prevent any static electricity build - up that could potentially lead to an ignition. The connection points for the power supply are also designed to be explosion - proof, with sealed connectors and proper insulation to prevent sparking.

Inside the housing, the electrical components are carefully selected and arranged to minimize the risk of ignition. The light source, which can be an LED (Light - Emitting Diode), a high - pressure sodium lamp, or a metal halide lamp, is connected to a power supply through a driver (for LEDs) or a ballast (for other types of lamps).

The driver or ballast is usually enclosed in a separate compartment within the housing to protect it from the external environment and to prevent any electrical arcing or sparking. The wiring is insulated with high - quality materials and routed in a way that avoids sharp edges or points that could cause wire abrasion and subsequent electrical faults.

When the fixed explosion - proof light is connected to a power source, the electrical current flows through the appropriate electrical components. For an LED - based light, the driver converts the input AC voltage to the suitable DC voltage for the LEDs. The LEDs then emit light through the process of electroluminescence.

In the case of other light sources such as high - pressure sodium or metal halide lamps, the ballast regulates the voltage and current to start and operate the lamp. The light is then emitted through the lens to illuminate the area.

The key safety aspect of the working principle is that the explosion - proof design contains any potential explosion within the housing. The sealed structure and carefully engineered electrical components prevent the release of energy that could ignite the surrounding explosive substances.

The primary advantage of a fixed explosion - proof light is its enhanced safety. By preventing the ignition of explosive atmospheres, it provides a secure lighting solution in hazardous areas, protecting lives and property.

The explosion - proof design also reduces the risk of accidents caused by electrical faults or overheating, which is especially important in environments where flammable substances are present.

The robust construction of the housing, lens, and mounting mechanism makes the light highly durable. It can withstand harsh conditions such as high humidity, corrosive chemicals, mechanical vibrations, and impacts. This durability ensures a long - term and reliable lighting solution.

Many modern fixed explosion - proof lights use LED technology, which is highly energy - efficient. LEDs consume less energy compared to traditional light sources such as high - pressure sodium or metal halide lamps. This not only reduces operating costs but also contributes to energy conservation and environmental sustainability.

These lights are designed to provide a consistent and uniform distribution of light. This is important for tasks that require good visibility, such as inspections, maintenance work, and operations in industrial plants. The proper light distribution helps to improve safety and productivity.

In oil refineries, petrochemical plants, and gas - processing facilities, fixed explosion - proof lights are used to illuminate process areas, storage tanks, loading docks, and pipelines. They provide the necessary light for workers to carry out operations such as equipment inspection, maintenance, and product transfer without the risk of explosion.

Chemical manufacturing plants with flammable vapors and dust rely on these lights to illuminate reaction vessels, storage areas, conveyor belts, and laboratory spaces. The explosion - proof design ensures that the lighting does not pose a threat to the safety of the chemical processes and personnel.

In underground and surface mines, fixed explosion - proof lights are used to light up tunnels, shafts, work areas, and equipment operation sites. They are essential in the presence of explosive gases such as methane and in dusty conditions to provide a safe working environment for miners.

In grain silos, flour mills, and food - processing plants, where combustible dust can accumulate, these lights are used to ensure proper illumination while minimizing the risk of dust explosions.