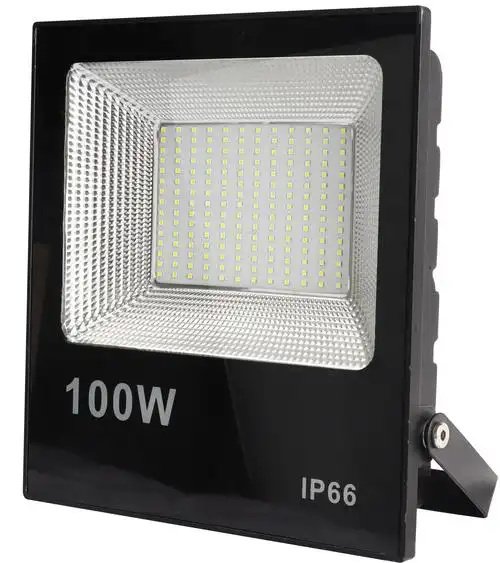

IP66 And Above Floodlights

The IP (Ingress Protection) rating is a standard used to classify the degree of protection provided by an enclosure against the intrusion of solid particles and liquids. The rating is composed of two digits. The first digit indicates the level of protection against solid objects, and the second digit represents the protection against liquids.

Protection Against Solids: The first digit '6' means that the floodlight is completely protected against dust ingress. It can effectively prevent even the tiniest dust particles from entering the interior of the floodlight. This is highly beneficial for floodlights used in environments such as industrial manufacturing plants, construction sites, and desert regions where dust is abundant. The sealed design safeguards the internal components like the light - emitting diodes (LEDs), drivers, and circuitry from dust - related damage, ensuring reliable and consistent performance over time.

Protection Against Liquids: The second digit '6' indicates that the floodlight can withstand powerful water jets. In a standard test, a floodlight with an IP66 rating is subjected to water projected at a high pressure (around 100 kPa) from a nozzle with a specific diameter from various directions. This makes IP66 floodlights suitable for outdoor applications where they may be exposed to heavy rain, water spray from cleaning equipment, or even water splashes caused by nearby water - related activities such as fountains or waterfalls.

IP67: The difference between IP66 and IP67 lies in the liquid - protection aspect. An IP67 - rated floodlight can be temporarily submerged in water up to a depth of 1 meter for a period of around 30 minutes. This enhanced water - protection feature makes it an excellent choice for applications where the floodlight might accidentally be immersed in water, such as in flood - prone areas, near swimming pools, or in marine environments (for short - term exposure).

IP68: IP68 - rated floodlights offer the highest level of water protection among these ratings. The exact depth and duration of submersion that an IP68 - rated device can withstand vary depending on the manufacturer's specifications. However, in general, it can handle more extended periods of submersion in deeper water than IP67 - rated floodlights. This makes IP68 floodlights suitable for applications such as underwater lighting in pools, fountains, or other water features where continuous water contact and submersion are part of the normal operating conditions.

Housing: The housing of IP66 and above floodlights is typically made of high - quality, durable materials. For example, die - cast aluminum is a common choice due to its excellent strength and corrosion - resistance properties. The housing is designed with multiple seals and gaskets to ensure a watertight and dust - tight enclosure. These gaskets are usually made of rubber or silicone materials that can maintain their sealing properties over a wide range of temperatures and environmental conditions.

Lens and Optics: The lens of these floodlights is also carefully designed to provide a good seal. It is often made of toughened glass or high - grade plastic that can withstand the pressure and environmental factors. The optical components inside, such as reflectors and diffusers, are protected from water and dust, ensuring that the light output and distribution remain consistent and efficient throughout the floodlight's lifespan.

Cable Entry and Connectors: Special attention is given to cable entry points to prevent water and dust from seeping in through the wires. High - quality waterproof connectors and cable glands are used to provide a secure seal. These connectors are designed to maintain electrical integrity even when exposed to water or other harsh environmental conditions.

Industrial and Construction Sites: In industrial settings, IP66 and above floodlights are used to illuminate work areas, storage yards, and machinery. Their resistance to dust and water makes them ideal for environments where heavy machinery operation, material handling, and dust - generating processes are common. In construction sites, they can provide reliable lighting during all weather conditions and in the presence of dust from excavation and building activities.

Outdoor Sports and Recreational Facilities: For outdoor sports stadiums, swimming pools, and water parks, these floodlights offer excellent illumination while withstanding the elements. IP66 floodlights can handle rain and water splashes during sports events, and IP67/IP68 floodlights are suitable for underwater or pool - side lighting, enhancing the safety and visibility of the area.

Marine and Coastal Environments: In marinas, docks, and coastal installations, IP66 and above floodlights are essential. They can endure the corrosive effects of saltwater spray, heavy rain, and high winds. IP67/IP68 - rated floodlights are particularly useful for illuminating boat interiors, piers, and other structures that may be exposed to water submersion during high tides or storms.

Regular Inspection: Despite their high - level protection, it is still necessary to regularly inspect IP66 and above floodlights. The seals, gaskets, and connectors should be checked for signs of wear, damage, or degradation. Any cracks or gaps in the seals can compromise the floodlight's protection and lead to water or dust ingress.

Cleaning: Cleaning the exterior of the floodlights is important to remove dirt, salt deposits (in coastal areas), or other contaminants that could potentially affect the performance of the light. However, care must be taken not to damage the seals during the cleaning process.

Long - Term Durability: With proper maintenance, IP66 and above floodlights can have a long lifespan. The high - quality construction and protection features ensure that the internal components are shielded from environmental factors, reducing the risk of premature failure due to water damage, corrosion, or dust accumulation. This makes them a cost - effective solution for applications where reliable and durable lighting is required over an extended period.