Industrial High Pressure Sodium Lamp

High - pressure sodium lamp industrial and mining lamps are specifically designed to meet the demanding lighting requirements of industrial and mining settings. These lamps are well - known for their high luminous efficacy and are widely used to provide bright and reliable illumination in large - scale, often - harsh working environments.

The high - pressure sodium lamp consists of an arc tube, which is the heart of the lighting mechanism. The arc tube is typically made of a special ceramic material. This material is chosen because it can withstand the high temperatures and pressures that occur during the operation of the lamp. Inside the arc tube, there is a mixture of sodium, mercury, and a small amount of noble gases such as xenon.

Surrounding the arc tube, there is usually an outer bulb. The outer bulb serves multiple functions. It provides protection for the arc tube from external factors such as mechanical shocks and environmental contaminants. It also helps to reduce the ultraviolet (UV) radiation emitted by the lamp, as excessive UV radiation can be harmful to the surrounding environment and human health.

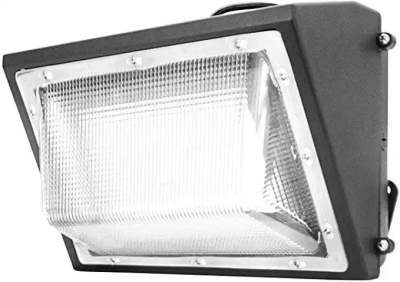

The reflector in a high - pressure sodium lamp industrial and mining lamp plays a crucial role in directing and concentrating the light output. It is usually made of a highly reflective material such as aluminum or a specialized reflective coating on a metal substrate. The shape of the reflector is carefully designed to achieve the desired light distribution pattern. For example, in mining applications, a wide - angle reflector might be used to illuminate a large area of a tunnel or a work surface. In industrial settings, a more focused reflector could be used to direct light onto a specific work area or machinery.

The lens of the lamp is another important component. It is often made of toughened glass or a high - quality, impact - resistant plastic. The lens is designed to transmit light efficiently while protecting the internal components of the lamp from dust, water, and physical impacts. It can also have properties to diffuse the light to some extent, providing a more even illumination across the target area.

The housing of these lamps is constructed to be robust and durable to withstand the rigors of industrial and mining environments. Materials such as cast aluminum or steel are commonly used. These environments can expose the lamps to corrosive chemicals, high levels of dust, and vibrations from heavy machinery. The housing is also designed with heat - dissipation features. High - pressure sodium lamps generate a significant amount of heat during operation, so proper heat management is essential. This is usually achieved through features such as heat sinks or fins on the housing to increase the surface area for heat dissipation.

The mounting options for high - pressure sodium lamp industrial and mining lamps are diverse. They can be mounted on walls, ceilings, poles, or mobile equipment. The mounting mechanisms are designed to be secure and stable, capable of supporting the weight of the lamp and withstanding any vibrations or movements associated with the operation.

The electrical components of the lamp include a ballast, which is a crucial element. The ballast is responsible for regulating the voltage and current supplied to the lamp. It ensures that the lamp starts and operates properly, and also provides protection against electrical surges and other power - related problems. The wiring inside the lamp is carefully insulated and routed to prevent short - circuits and electrical hazards. Connectors and terminals are designed to be reliable and secure to avoid loose connections that could lead to sparking.

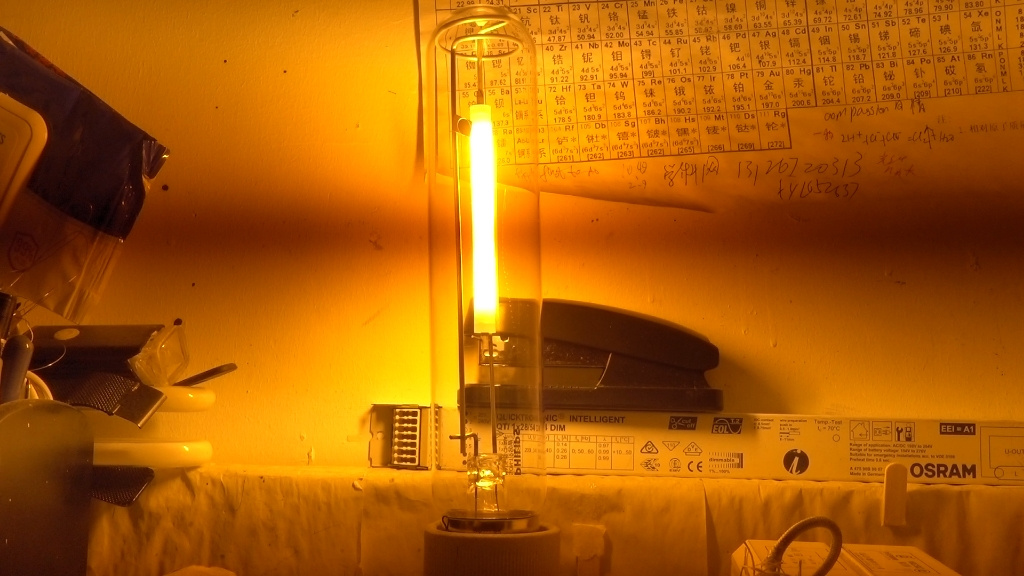

When the lamp is powered on, the ballast provides an initial high - voltage pulse to start the ionization process. The noble gas (such as xenon) in the arc tube ionizes first due to its lower ionization energy. This creates a conducting path for the electrical current.

As the current flows, the mercury vaporizes and ionizes, forming a plasma. The heat from the mercury plasma then vaporizes the sodium. The ionized sodium atoms emit a characteristic yellow - orange light through a process called radiation. The light output is a result of the transitions of electrons in the sodium atoms between different energy levels.

The light emitted from the arc tube is then directed and focused by the reflector and passes through the lens to illuminate the area. The outer bulb helps to contain and manage the light, reducing UV radiation and protecting the internal components.

High - pressure sodium lamp industrial and mining lamps have a high luminous efficacy. They can produce a large amount of light output using relatively less energy compared to some other light sources. This energy - efficiency makes them an ideal choice for large - scale lighting in industrial and mining settings where a significant amount of illumination is required.

These lamps generally have a relatively long service life. The combination of the durable construction of the lamp and the stability of the high - pressure sodium lamp's internal components allows them to operate for an extended period. This reduces the frequency of lamp replacement, which is beneficial in terms of maintenance cost and labor.

The yellow - orange light of high - pressure sodium lamps has good penetration characteristics in foggy, dusty, or hazy conditions. This makes them suitable for outdoor industrial and mining applications such as lighting in mining yards, ports, and areas where visibility can be affected by environmental factors.

In underground and surface mining operations, high - pressure sodium lamp industrial and mining lamps are used to light up tunnels, work areas, and equipment operation sites. The long - range light penetration and explosion - proof features (if applicable) are especially valuable in the presence of explosive gases such as methane and in dusty conditions.

In large - scale industrial plants such as steel mills, chemical factories, and power plants, these lamps are used to illuminate work areas, storage yards, and production lines. The high - intensity light helps workers to carry out their tasks efficiently and safely. The energy - efficiency also makes them a cost - effective lighting solution for such large - area applications.